Maintenance with Slashes Factory Stops by 30%

How Machine Learning Predictive Maintenance Cut Factory Downtime by 30% Unplanned downtime in manufacturing can be devastating delaying production driving up costs and hitting revenue...

⏱️ Estimated reading time: 3 min

Latest News

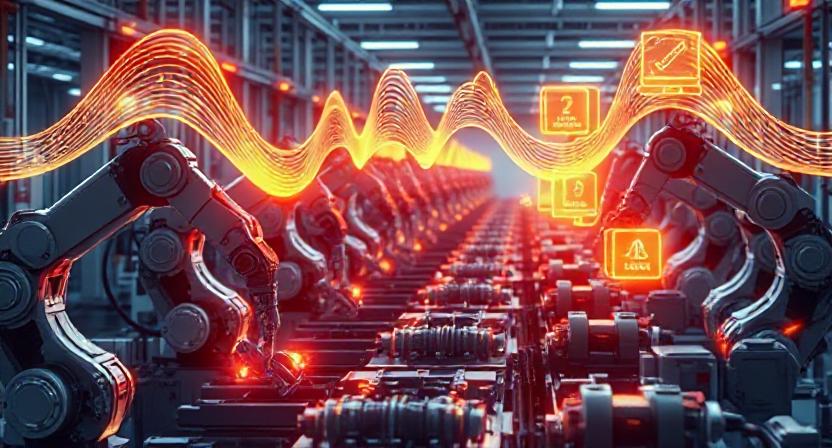

How Machine Learning Predictive Maintenance Cut Factory Downtime by 30%

Unplanned downtime in manufacturing can be devastating delaying production driving up costs and hitting revenue hard. In 2024 alone the world’s top 500 manufacturers faced up to $1.4 trillion in unplanned downtime losses Business Insider. Many companies are turning to machine learning powered predictive maintenance PdM to address this. The results are now showing that these systems can reduce downtime by as much as 30% reshaping factory operations.

What Is Predictive Maintenance?

Unlike traditional preventive scheduled or reactive post-failure maintenance predictive maintenance instead uses real-time sensor data to determine when a machine is likely to fail. As a result it can trigger maintenance only when needed.

- Analyzing historical and real-time data e.g. vibration temperature

- Detecting anomalies that precede failures

- Forecasting equipment health to schedule repairs proactively

- Continuously improving predictions as machines operate

A Deloitte report noted these systems can reduce unplanned downtime by up to 50% while also lowering maintenance costs by 25–30%

Manufacturing Plant – 30% Downtime Reduction

A global manufacturing company deployed ML for assembly line robots using sensor data to anticipate failures and schedule maintenance during off-hours. Consequently this resulted in a 30% drop in downtime. Moreover the company achieved substantial cost savings and increased productivity.

Automotive Supplier in Ohio

An automotive parts plant in Ohio implemented sensors and ML tools on its stamping line. As a result unplanned stoppages dropped by 37% after six months and ultimately by 42% after a year.

Industry-Across Review

An academic analysis reported that industries that used predictive maintenance reduced their unplanned downtime by 30–40% when compared to traditional methods. Consequently predictive maintenance demonstrates clear advantages over older approaches.

How Predictive Maintenance Delivers a 30% Downtime Cut

Early Anomaly Detection

Sensors and ML models flag deviations well before they lead to breakdowns giving maintenance teams a proactive edge .

Optimized Scheduling

Maintenance shifts from reactive firefighting to pre-planned actions during off-peak hours minimizing disruption .

Fewer False Alarms

ML systems can also reduce unnecessary interventions by distinguishing real failure signals from noise .

Continuous Model Improvement

As more data is collected, ML models get smarter and more accurate at predicting failures .

Strategic Asset Allocation

Planners can prioritize maintenance on high-risk equipment further reducing unexpected downtime and costs .

Overcoming Implementation Challenges

Despite the clear ROI deploying ML-driven PdM comes with hurdles:

- However, a high upfront investment is required for sensors and infrastructure.

- Integration with legacy systems can be complex

- Data quality issues undermine model accuracy

- Talent shortages make adoption harder for many teams

Recommendations for Successful Adoption

- Start Small

Pilot PdM on a single line or machine to validate ROI. - Ensure Data Quality

Invest in good sensors clean data collection and integration layers. - Upskill the Workforce

Train teams to trust and interpret ML insights not just rely on them blindly. - Partner Strategically

Collaborate with AI experts or vendors experienced in PdM. - Measure ROI

Track reductions in downtime maintenance cost savings and increased output to justify expansion.

Related Posts

Sakana AI Secures $135M to Advance AI in Japan

Sakana AI Raises $135M to Advance AI in Japan Sakana AI recently secured $135 million...

November 17, 2025

AI Takes the Field Oakland Ballers’ Bold Experiment

Oakland Ballers Bet on AI A Risky Play? The Oakland Ballers a team in the...

September 22, 2025

AI Boom Billion-Dollar Infrastructure Investments

The AI Boom Fueling Growth with Billion-Dollar Infrastructure Deals The artificial intelligence revolution is here...

September 22, 2025

Leave a Reply